3D Bioprinting tissue isn’t a new idea, yet the method, so far, has been limited to tissues that are very small or very thin and lack blood vessels. Signs of Progress have been made across the globe. We have already seen lab-grown ears, bladders, blood vessels, and other parts implanted in patients and the world’s first bioprinted tibia transplant. We’ve also seen how a 3D printed prosthetic hands changed a few kids’ lives. And, yes, the medical world has not reached that point where it can 3D bioprint a fully functional human heart, yet scientists do believe that day is only a few years away. Here are some of the most relevant 3D bioprinting breakthroughs registered in 2018’s first six months that are worth looking at, if you share my interest in emerging technologies able to change the face of modern medicine.

Super soft structures that replicate the brain and lungs

Back in January 2018, Imperial College London researchers announced that their new 3D printing technique allows researchers to replicate biological structures, which could be used for tissue regeneration and replica organs. To do so, they use using cryogenics (freezing) and 3D printing techniques.

According to Zhengchu Tan, one of the researchers from the Department of Mechanical Engineering at Imperial, „At the moment we have created structures a few centimetres in size, but ideally, we’d like to create a replica of a whole organ using this technique.”

But, there are two things this new approach can bring to the medical world and benefit patients in need of complex surgeries and organ transplants:

- Tissue regeneration – being able to match the structure and softness of body tissues, means that these structures could be used in medical procedures to form scaffolds that can act as a template for tissue regeneration, where damaged tissues are encouraged to regrow.

- Replica body parts and organs – this technique could be used to create replica body parts or even whole organs. This could turn out to be of huge help to scientists as it would allow them to carry out experiments not possible on live subjects. As well, they could even be used to help with medical training, replacing the need for animal bodies to practise surgery on.

3D printing of living cells

Just one month later, University of Twente, Netherlands, scientists announced that they were successful in printing 3D structures with living cells. This special technique enables the fast and ‘in-flight’ production of micro building blocks that are viable and can be used for repairing damaged tissue, for example. As opposed to other 3D printing techniques using heat or UV light both potentially damaging living cells, this microfluidic approach is extremely promising as the damaged tissue is repaired by using cultured cell material of the patient.

Successfully 3D bioprints of human heart tissues

BIOLIFE4D, a Chicago-based medical tech firm specializing in 3D bioprinting and tissue engineering, announced it has successfully demonstrated its ability to 3D bioprint human cardiac tissue, namely a human cardiac patch. The whole process was completed in just a few days and much sooner than anticipated. What makes BIOLIFE4D’s bioprinting process so special is the fact that it provides the ability to reprogram a patient’s own (white) blood cells to iPS cells. Also, it differentiates the iPS cells into different types of cardiac cells needed to 3D bioprint not only a cardiac patch but a human heart viable for transplant. For BIOLIFE4D the next steps will be on will be constructing valves, blood vessels and a mini-heart as it seeks to progress to 3D bioprinting a full human heart.

World’s first 3D-printed cornea

In May 2018, scientists at Newcastle University, UK, have 3D-printed the first human corneas. This is quite an amazing piece of news for all those people already suffering or being threatened by blindness. Their research claims that it took only 10 minutes to obtain the 3D-printed cornea that matched the patient’s unique specifications (size and shape). However, this is just the beginning and it will take several years the improve the technique, so it can be used on real patient transplants in hospitals.

This is a huge breakthrough in the world of ophthalmology, considering the shortage of corneas available for transplants. Worldwide there are around 10 million people requiring surgery to prevent corneal blindness. In addition, The World Health Organisation estimates that another 4.9 million people suffer from total blindness due to corneal scarring. According to Che Connon, Professor of Tissue Engineering at Newcastle University,

„Our 3D printed corneas will now have to undergo further testing and it will be several years before we could be in the position where we are using them for transplants. (…) However, what we have shown is that it is feasible to print corneas using coordinates taken from a patient eye and that this approach has the potential to combat the world-wide shortage.”

The best possible functioning capillaries

Founded in 2016 by research scientists Melanie Matheu and Noelle Mullin, Startup Prellis Biologics, bets on new technology to manufacture capillaries, the one-cell-thick blood vessels that are the pathways which oxygen and nutrients move through to nourish tissues in the body. Without well-functioning capillaries, to make organs viable for human transplants. Prellis recently published research findings claiming their technology is able to manufacture capillaries at a size and speed that would deliver 3D-printed organs to the market within the next five years. The startup uses holographic printing technology that creates three-dimensional layers deposited by a light-induced chemical reaction that happens in five milliseconds. This feature, according to the company, is critical for building tissues like kidneys or lungs.

Although Prellis Biologics now focuses on perfecting a technique for printing kidneys, Matheu states that their technology “ (…) will come to market in many other ways prior to the full kidney.”

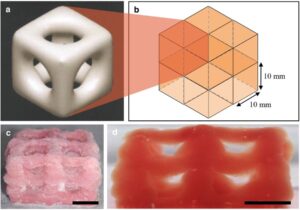

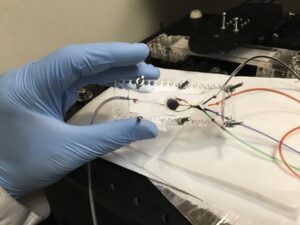

Complex biological tissues

Only last month, UCLA Samueli-led team revealed that they developed a specially adapted 3D printer to build therapeutic biomaterials from multiple materials. This is quite a medical breakthrough as tissues are so complex structures, so to engineer artificial versions of them that function perfectly. Therefore, replica tissues must recreate their original complexity. Using different materials make this possible. The technique uses a light-based process called stereolithography, and it takes advantage of a customized 3D printer designed by Ali Khademhosseini, Professor of Engineering at the UCLA Samueli School of Engineering, that has two key components. The first is a custom-built microfluidic chip with multiple inlets that each „prints” a different material. The other component is a digital micromirror, an array of more than a million tiny mirrors that each moves independently. The researchers used different types of hydrogels. The printed structures were tested by implanting them in rats. The structures were not rejected, so there is much hope. This could mean a step toward on-demand printing of complex artificial tissues for use in transplants and other surgeries.

3D bioprinting technology for orthopaedic surgeries

Just this week, INTAMSYS, a leader in polyether ether ketone (PEEK) 3D bioprinting technology and additive manufacturing and the Department of Orthopaedic Surgery at the University of California (UCSF), San Francisco, announced a joint-research initiative to advance 3D printing applications in the field of orthopaedic surgery. Doctors hope this partnership with INSTAMSYS will help them prototype customized implants using high-temperature materials such as PEEK. (Polyetherketoneketone (PEEK) is a semi-crystalline thermoplastic often used in extreme operating environments because the material exhibits superior ablative characteristics that include flame and ultraviolet radiation retardancy, superior chemical resistance, excellent heat release, extremely low outgassing and toxicity.

New printing approach from Stanford University

The last, but not least important approach that could potentially revolutionize medicine comes from Dr Utkan Demirci, Radiology Professor at the Stanford University School of Medicine. As opposed to regular bioprinting techniques relying on growing constructs on tissue scaffolds, Demirci and his team focus all their efforts on biofabrication through the self-assembly of cells. In addition, they investigate biomanufacturing cellular constructs in the absence of a gravitational force field. The aim is to see whether tissue could be engineered in space. In an interview for physicsworld.com, Demirci

“However, we would ultimately like to precisely code 3D multicellular complex living materials, which is an exciting challenge given their architectural complexity and spatiotemporal heterogeneity.” (…) Such techniques, which would build living materials with 3D control over geometry and organization, might be able to create model systems that mimic the physiological as well as pathological behaviour of native tissues,” he continues. “Such models might be extremely valuable in cancer for precision medicine to better care for patients.”

Transforming the industry

3D bioprinting definitely gets the medical world’s attention! Whether scientists working at Harvard, Newcastle, Twente, Stanford or visionary biotech startup founders, they all have shared the same dream of one day successfully eliminating the need for donor organs. Yet, as we speak all their efforts concentrate on creating the best possible 3D printed tissues or body parts. They are all hoping the day when fully-functional organs are ready for human transplants is not very far. If organs could be manufactured in large numbers, it wouldn’t only solve the organ. It would eventually reshape human life span. Can you imagine getting a new heart or lungs at 80? And, of course, it would definitely change the way some industries operate. Just imagine the implications for insurance companies or the governments paying the pensions! Therefore, medicine is another field disrupted for the better by the new emerging technologies.